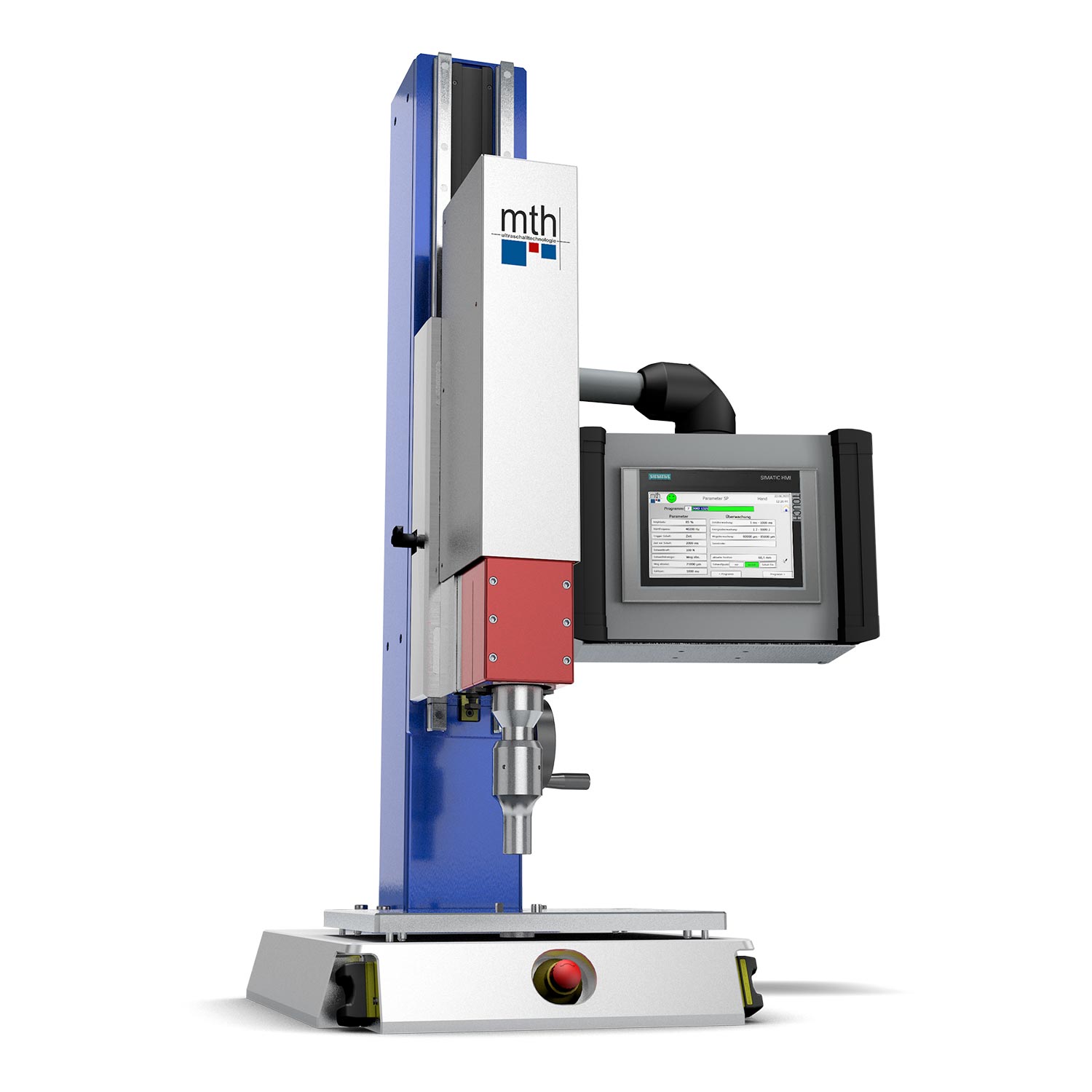

Ultrasonic welding machine TSM 20, bench-top version

With pneumatic feed

Ultrasonic welding machine TSM 20 performance, bench-top version

With our ultrasonic welding machine you can weld all common thermoplastics, e.g. ABS, PA or PP. It is characterized by a large working area as well as high bending rigidity and positioning accuracy. Optimum welding results, even when high forces are required or with unfavorable geometries, are guaranteed by generously dimensioned recirculating ball guides and a robust welding machine base.

As a result, this bench-top welding machine has a wide range of applications and is therefore used in these industries for various ultrasonic welding work: automotive industry, medical technology, electrical industry, packaging industry and toy industry.

Technical Data

| Working stroke: | 100 mm |

| Head height: | max. 400 mm |

| Power: | 2.000 W |

| Frequency: | 20 kHz |

| Amplitude: | 50 .. 100% |

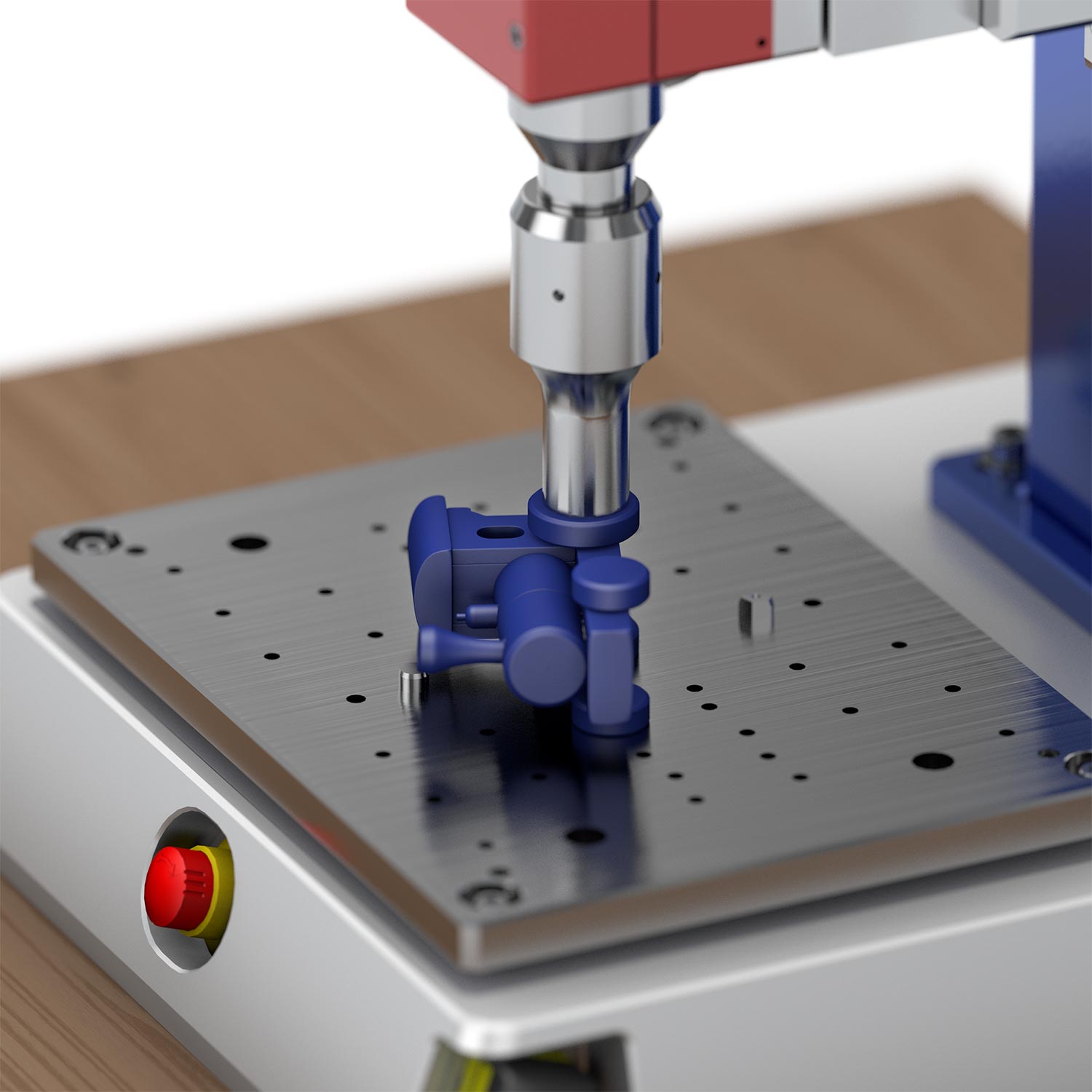

| Clamping surface: | 300 mm x 400 mm |

| Welding force: | 50 – 3.000 N (via electrical adjustable proportional valve) |

The ultrasonic welding machine TSM 20 performance is built on a machine base machined from solid and anodized and is therefore very torsion-resistant. The tool clamping plate with hole pattern 8H7 and M8 is also equipped with a finely adjustable angle compensation and can therefore be aligned precisely. Furthermore, the column made of closed steel tube encloses the internal height adjustment so that it is protected against external influences. The recirculating ball guides in both the welding unit and the head height adjustment are also of the highest quality. For the manual head height adjustment, a generously sized trapezoidal thread spindle with precision gear and clamping on both sides is used.

Scope of delivery ultrasonic welding machine TSM 20 performance

- Ultrasonic generator K3 with 2000 watts at 20 kHz

- Ultrasonic converter

- Booster 1:1.5

- Fine-resolution position measuring system (typically 0.05 mm)

- Calibrated load cell

- Siemens PLC control with 9″ touch display

- 2-hand operation with touch buttons, easy to clean

Basic functions

Although the TSM 20 performance ultrasonic welding machine has a pneumatic drive, the integrated force measurement allows the sontotrode weight to be precisely balanced so that the welding force can be precisely controlled at any time. The basic functions also include the welding modes welding via absolute distance, incremental distance, time or energy. In addition, welding can begin using a trigger force, a waypoint and also after a lead time has elapsed. In addition, 100 parameter sets can be archived on a USB stick.

Ultrasonic welding machine – areas of application

Ultrasonic plastic welding is also used for large-volume automotive series parts in the areas of interior trim, controls, lighting and engine components. The TSM 20 Performance ultrasonic welding machine, table version, can be used universally in many areas, which means it can be set up for many different welding tasks.

- Medical technology: In medical technology, our ultrasonic table welding machine is used, for example, for protective masks, infusion material and ventilators.

- Electrical industry: In the electrical industry, plastic welding takes place in such a way that pump impellers, switching elements, connectors and small housings are welded.

- Packaging industry: Ultrasonic welding is one of the standards for transparent packaging, identity seals and trading card grading.

- Toy industry: Children’s toys, pool accessories and fittings are also welded using ultrasound due to their high cost-effectiveness.

Downloads